Planes are the epitome of fine woodworking and have four jobs in the shop: to straighten, flatten, smooth and remove wood. Simple, but many woodworkers are confused by all the different sizes of bench planes available. Stanley has at least 15+ planes, from the tiny 5-1/2″-long No. 1 smooth plane (If you have one of these let me know I gladly give you $500 for it), up to the monstrous 24″- long No. 8 jointer plane. Check out The Superior Works Perhaps the webs best repository of plane info.

Basically a plane, in its simplest form, is a chisel held at a fixed angle, and there are many, many, many different styles of hand planes designed for specific purposes. Some made entirely of metal – others made from wood with steel parts. Most are meant to smooth the surface, some with blades designed to cut profiles and some to cut curves. There is even one (toothing plane) designed to roughen the surface.

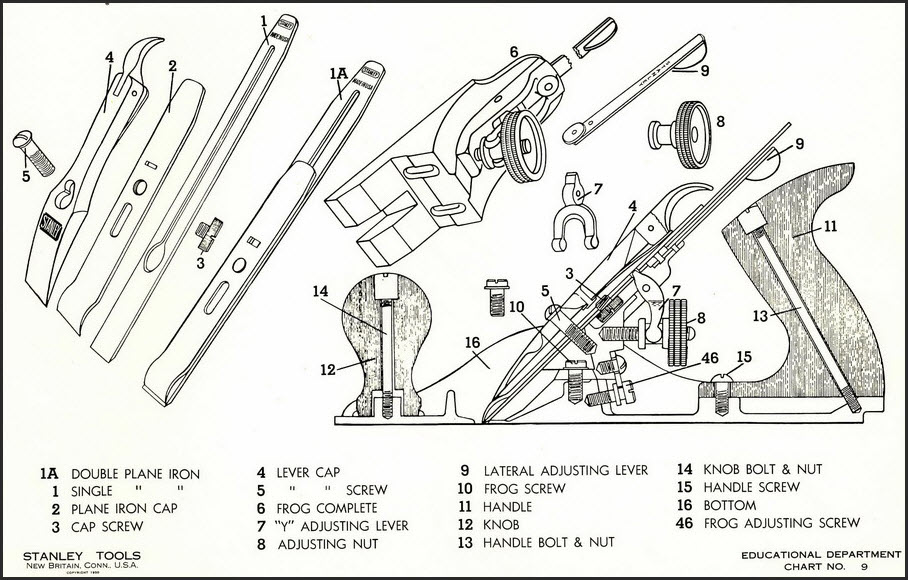

Here you see the basic parts of a typical Stanley No. 4 adjustable smoothing plane.

Although there are a variety of styles – there are four basic planes: Jack, Jointer, Smoothing and Block. I have also given a link to online auctions.

The Jack Plane (Stanley No 5) is unquestionably the most versatile plane in my shop. Its purpose is to remove a large amount of wood across the grain in a short period of time. With a length of 14″, the iron is 2½” wide and can be honed to a curve with about an 8″ radius or just slightly rounded. This produces a scallop effect on the surface (less pronounced than the scrub plane). Some have a grooved sole to reduce friction. Once planed with the jack plane the surface will typically be left with scalloped grooves perpendicular to or at an angle to the grain. If I could buy only one bench plane, I would opt for a vintage Stanley No. 5 Available here The Jack Plane (Stanley No 5) is unquestionably the most versatile plane in my shop. Its purpose is to remove a large amount of wood across the grain in a short period of time. With a length of 14″, the iron is 2½” wide and can be honed to a curve with about an 8″ radius or just slightly rounded. This produces a scallop effect on the surface (less pronounced than the scrub plane). Some have a grooved sole to reduce friction. Once planed with the jack plane the surface will typically be left with scalloped grooves perpendicular to or at an angle to the grain. If I could buy only one bench plane, I would opt for a vintage Stanley No. 5 Available here |

||||

The Jointer plane – also called the tri plane. Designed to plane long edges flat and square. Jointing simply prepares the edges of boards to be joined together – although it can, and is frequently used to flatten surfaces. There is a shorter version of the jointer plan called a fore plane around 18 inches, I’m guessing it’s called fore because one used it Before the Jointer. The jointer’s long sole will ensure that the iron only slices high spots (the tops of the scallops) producing short shavings. As these high spots are sliced off, the shavings will become longer and longer, until you get a straight edge, which will give you a shaving the entire length of the board. The Jointer plane – also called the tri plane. Designed to plane long edges flat and square. Jointing simply prepares the edges of boards to be joined together – although it can, and is frequently used to flatten surfaces. There is a shorter version of the jointer plan called a fore plane around 18 inches, I’m guessing it’s called fore because one used it Before the Jointer. The jointer’s long sole will ensure that the iron only slices high spots (the tops of the scallops) producing short shavings. As these high spots are sliced off, the shavings will become longer and longer, until you get a straight edge, which will give you a shaving the entire length of the board. The sole of the jointer plane is flat, wide and long. My No 7 jointer is 22″ long and 3″ wide really heavy, but with continual use you do get used to its weight. I have an even bigger wooden jointer that’s 26″ and heavy! Unlike the Jack plane, the iron of the jointer is honed square, although I tend to ’round’ off the edges of mine so as not to leave cut marks on the surface of board – Available here The sole of the jointer plane is flat, wide and long. My No 7 jointer is 22″ long and 3″ wide really heavy, but with continual use you do get used to its weight. I have an even bigger wooden jointer that’s 26″ and heavy! Unlike the Jack plane, the iron of the jointer is honed square, although I tend to ’round’ off the edges of mine so as not to leave cut marks on the surface of board – Available here |

||||

The Smoothing Plane – Before the widespread use of sandpaper woodworkers used smoothing planes to prepare their work for final finish. It was the ‘smoother’ that the master craftsman used to achieve the mirror-like finishes seen in many examples of fine furniture. A finely tuned smoothing plane will produce a clear bright finish to surfaces devoid of the furriness created by sandpaper. Available here The Smoothing Plane – Before the widespread use of sandpaper woodworkers used smoothing planes to prepare their work for final finish. It was the ‘smoother’ that the master craftsman used to achieve the mirror-like finishes seen in many examples of fine furniture. A finely tuned smoothing plane will produce a clear bright finish to surfaces devoid of the furriness created by sandpaper. Available here |

||||

The block plane is small one-handed plane about 6″ long with a low angle iron set with the bevel up. It is designed for single handed use and to cut end grain. The name is probably derived from that fact that butcher’s blocks were made with the end grain uppermost. It is typically held at 45 degrees to the direction of travel. The block plane has many uses – including cleaning up joints and creating chamfers. Among hand planes, I would ranks the Block Plane near the top for versatility and convenience and certainly one that I reach for for all manner of planing tasks. Available here The block plane is small one-handed plane about 6″ long with a low angle iron set with the bevel up. It is designed for single handed use and to cut end grain. The name is probably derived from that fact that butcher’s blocks were made with the end grain uppermost. It is typically held at 45 degrees to the direction of travel. The block plane has many uses – including cleaning up joints and creating chamfers. Among hand planes, I would ranks the Block Plane near the top for versatility and convenience and certainly one that I reach for for all manner of planing tasks. Available hereHere you can see the block plane being used to bring edge trim flush to shelf. |

||||