I knew I had a problem when cherry and maple started go through the table saw and get scotched. There are several reasons this can happen:

Dull Blade, Dirty Blade, Feed rate too slow, Warped blade, Misaligned fence, Riving Knife misaligned or Warped Wood.

After ruling out most of these it appeared that the fence had moved out of alignment by about .0006″ towards the back of the blade. Wood was getting pinched between the fence and the riving knife making the feed rate slower as it was being ripped. So a relatively easy fix. After a few passes through the saw the issue appeared to have been resolved…

Or so I thought.

If this was all I did on a table saw then I could live with the blade being parallel to the fence, but I have recently been making some deep shadow boxes that require mitred corners and no matter how hard I tried they were not cutting square. Checking the mitre gauge alignment to the saw revealed that it was .0006″ wider at the back of the saw than the front.

At this point I realized that the table was actually no longer in alignment with the saw and I needed to consult the manual.

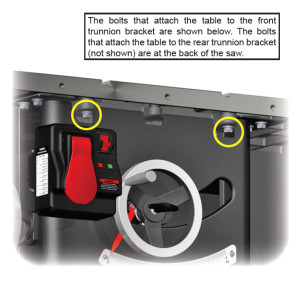

I just love the annotation – ‘the bolts that attach the table to the rear trunnion brackets (not shown) are at the back of the saw’. The operative phrase is not shown. Since it is almost impossible to see them and they are only accessible through the saw blade opening with the blade removed and for the left bolt the blade has to be tilted 45 degrees. None of this is mentioned in the otherwise excellent manual.

I just love the annotation – ‘the bolts that attach the table to the rear trunnion brackets (not shown) are at the back of the saw’. The operative phrase is not shown. Since it is almost impossible to see them and they are only accessible through the saw blade opening with the blade removed and for the left bolt the blade has to be tilted 45 degrees. None of this is mentioned in the otherwise excellent manual.

After ½hr I had the saw aligned within .0002″ and I was back in business.

While the saw is semi-together I might as well do an upgrade that I had been wanting to do since getting rid of my old table saw. A router table insert. Stay tuned…

There are many that you can use – drop box is one – when you post a link to a file in drop box it converts it to a live view – the same is true of Youtube – however – I would highly recommend that any links are to images that are reduced in size – the last thing we want is for LAP to grind to a stop because the server is bogged down with trying to display a 20MB image.

https://www.dropbox.com/s/t33lsaf2lr7lj6g/Fig.%2015%20Pegged%20mortise%20and%20tenon%20%20joint%20in%20a%20medieaval%20barn%20-%20note%20the%20marriage%20marks%20to%20make%20for%20easy%20reassembly_resize.JPG?dl=0